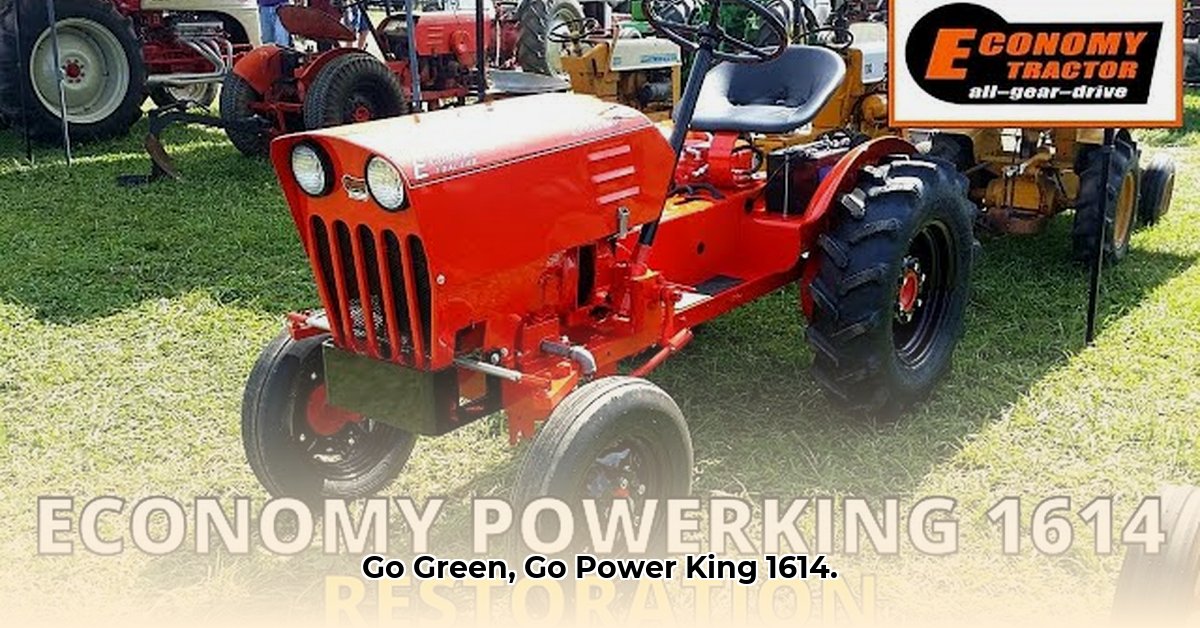

Power King 1614: A Sustainable Farming Solution?

Is a vintage tractor a viable option for modern, eco-conscious farming? The Power King 1614, a garden tractor manufactured between 1977 and 1993, presents a compelling case study. This article explores its strengths and weaknesses within the context of sustainable agriculture, providing actionable insights for various stakeholders. How can a machine from a bygone era contribute to a greener future? Let's examine the data. For more information on Power King tractors, visit the Power King resource.

Built to Last: The Power King's Enduring Durability

The Power King 1614's extended production run speaks volumes about its robust design. Its reputation for longevity contributes significantly to its environmental appeal. Unlike modern tractors frequently requiring replacement, the 1614 offers a longer lifespan, reducing manufacturing waste and the associated carbon footprint. Furthermore, its relatively simple mechanical design simplifies repairs, often eliminating the need for specialized parts or costly mechanic visits. This inherent repairability further enhances its sustainability profile.

Fuel Efficiency: A Smaller Footprint

While its 14-horsepower Kohler engine and modest fuel tank might seem inadequate compared to modern counterparts, the 1614 demonstrates impressive fuel efficiency for its intended tasks. For smaller farms and gardens, the reduced fuel consumption translates to lower operational costs and a significantly smaller carbon footprint. A smaller engine means less fuel burned, making it an appealing option for environmentally conscious small-scale farmers. Isn't reduced fuel consumption a key element of sustainable farming?

Operational Capabilities: A Realistic Assessment

It's crucial to acknowledge the Power King 1614's limitations. Its 9-speed transmission, while advanced for its time, pales in comparison to modern, sophisticated systems. Its compact size restricts its application to smaller-scale operations. While suitable for tasks such as tilling gardens or mowing small fields, it's not designed for large-scale farming. Choosing the right tool for the job aligns with sustainable practices; the 1614 shines in niche applications but falls short in others. What tasks does your farm require?

Environmental Considerations: A Lifecycle Perspective

While the 1614's longevity reduces its overall environmental impact, it's essential to consider its manufacturing origins. Environmental regulations were less stringent during its production era (1977-1993), potentially impacting its overall lifecycle assessment. However, ongoing research is exploring the holistic environmental effect of vintage farm equipment, offering a wider perspective on its overall sustainability. This ongoing analysis will better inform future decisions regarding the use of vintage machinery. What factors should drive our purchasing decisions in order to help the environment?

Stakeholder Benefits: A Multifaceted Approach

The Power King 1614 holds potential for several key stakeholders:

- Small-scale farmers: Its affordability, durability, and ease of maintenance make it an attractive option for those with limited budgets.

- Researchers: The tractor provides valuable data on the design principles of enduring, efficient machinery. This information can inform the development of more sustainable farming equipment in the future.

- Equipment manufacturers: Studying its design could inspire innovations in sustainable technology. The 1614’s ruggedness and simplicity are valuable lessons.

- Policymakers: Incentivizing the restoration and reuse of vintage equipment can stimulate local economies and promote sustainable farming practices.

Actionable Intelligence: A Practical Guide

This section outlines potential actions for different stakeholders, focusing on short-term and long-term strategies.

| Stakeholder Group | Short-Term Actions (0-1 year) | Long-Term Actions (3-5 years) |

|---|---|---|

| Small-Scale Farmers | Source parts; consider tractor restoration. | Explore alternative fuels (e.g., biodiesel); adapt to specific needs. |

| Researchers | Study longevity and efficiency. | Develop sustainable production models using vintage equipment. |

| Equipment Manufacturers | Analyze design for improved durability. | Develop modular designs for easier repair and reduced waste. |

| Policymakers | Support restoration and reuse policies. | Integrate lifespan and repairability into equipment regulations. |

Risk Assessment Matrix: Potential Challenges

Understanding potential risks is crucial for informed decision-making.

| Component/System | Short-Term Risk (0-1 year) | Long-Term Risk (3-5 years) | Mitigation Strategy |

|---|---|---|---|

| Kohler Engine (512cc) | Parts scarcity; engine failure. | Parts scarcity; engine failure. | Build a parts network; consider engine rebuilds. |

| Mechanical Transmission | Wear and tear; potential failure. | Difficulty finding replacements. | Regular maintenance; develop repair protocols. |

| Hydraulic System | Leaks; component failure. | Seal and hose degradation. | Preventative maintenance; early detection and repair. |

Legal and Regulatory Compliance

Remember, the Power King 1614 predates many current regulations. Prior to operation, ensure compliance with all local emission, noise, and safety standards. This is crucial for responsible and legal farming. Contact your local authorities for specific details.

Biodiesel Conversion: A Path to Greater Sustainability

Converting a Power King 1614 to run on biodiesel offers a path towards enhanced sustainability. While not a simple task, it represents a significant step in reducing reliance on fossil fuels.

Biodiesel Conversion: A Step-by-Step Guide

Disclaimer: Biodiesel conversion requires expert assistance. This is a simplified overview.

- Assessment: Thoroughly inspect the engine and fuel system.

- Fuel System Modifications: Modify fuel injectors, pump, and lines to accommodate biodiesel.

- Engine Adjustments: Calibrate the fuel delivery system for optimal biodiesel performance.

- Testing: Test the system extensively, gradually transitioning to 100% biodiesel.

- Maintenance: Implement a robust maintenance schedule, including frequent fuel filter changes.

Advantages and Disadvantages of Biodiesel Conversion

| Advantages | Disadvantages |

|---|---|

| Reduced reliance on fossil fuels | Higher initial costs |

| Lower greenhouse gas emissions | Increased maintenance requirements |

| Support for sustainable agriculture | Regional biodiesel availability variations |

| Potential cost savings (depending on fuel) | Requires specialized knowledge and expertise |

Conclusion:

The Power King 1614, while a vintage tractor, offers a compelling case study in sustainable farming practices. Its durability, fuel efficiency, and potential for biodiesel conversion make it a valuable asset for eco-conscious farmers, researchers, and policymakers alike. Careful consideration of its capabilities and limitations, coupled with a proactive approach to maintenance and potential upgrades, allows for a responsible integration of this vintage machine into modern sustainable agriculture.